tags:

weston snowboards |vail businesses |upstarts and underdogs |teton gravity research |splitboards |microbrew snowboards |mackenzie ryan |karakoram |barry clark

Welcome to Upstarts and Underdogs. This monthly column aims to showcase both up-and-coming brands and brands that have been quietly operating outside the spotlight. Arguably, these companies are shaping the future of snowboarding—and protecting its culture and soul.

Weston's headquarters in Minturn, Colorado. Photo by Chris Miller Photography (

Weston founder Barry Weston Clark in the Northern Chugach. Photo by Dominique Taylor.

Reclaiming Beetle-kill Pines

“The timber industry was just a way of life where I grew up,” Clark explains. “I love everything about wood. I think healthy forest management includes cutting down unhealthy trees and harvesting them in a way that they can be used.”

“Originally, we thought we could mill beetle-kill in a way that it could be used for a topsheet—I think the blue stain is beautiful. But beetle-kill can’t work for creating a veneer because of the knots. Then we experimented with using it as a core for a snowboard. The first experiment we used half beetle-kill and half poplar, plus a maple topsheet for rigidity. It worked great; it was really well received. We made the base material so that you can see the core.

“This year, we’re using 20% beetlekill pine and 80% aspen to make the boards a little bit stiffer. I really like how aspen pops. Beetle-kill has a light and nice structure; it’s like a secret sauce. I love how the aspen and beetle-kill work together. It’s all Colorado wood.

“There was a huge amount of aspen groves downed by windstorms in Routte County by Steamboat Springs. I’m happy that we are able to use some of that. It’s meaningful and preserves healthy trees. For every strand of beetle-kill and downed aspen, we don’t have to chop down a live tree.”

Scoring Feedback from Riders—and a Partnership with Karakoram

With a hub in Minturn, located between Vail Mountain and Beaver Creek, Weston’s headquarters is uniquely situated to get feedback from a large group of hardcore Colorado freeriders. Clark calls that immediate feedback one of the hallmarks of his company’s business model.

“We want a rider to come into our store and tell us what they felt,” Clark says. “[This] interaction with riders is atypical in snowboard manufacturing. I’m not hiding in an office somewhere. I’m available to talk. I don’t know everything about snowboard building. I have a lot to learn. It’s going to be really beneficial in the long-term."

Weston team rider Joe Otemba boosting a method in the Beaver Creek Backcountry. Photo by Mike Hood.

"There has never been a snowboard manufacturer in the Vail Valley. It’s a little baffling with all the skier visits and the talent that we have in terms of riders. It’s the perfect place to be. We can press a board and ride the same day. It keeps us connected to the industry in a unique and powerful way.”

Bryce Kloster, who co-founded Karakoram with his brother, Tyler, partnered with Weston for exactly this reason. “We like working with local brands, US-made brands,” says Kloster. “I feel like the smaller brands, not huge companies, are the core of splitboarding. These companies are more intact with people who are out there splitboarding. Getting the feedback is what makes us better.”

“People within the Colorado community know Weston Snowboards,” Kloster continues. “And we know Weston works with local riders down there.”

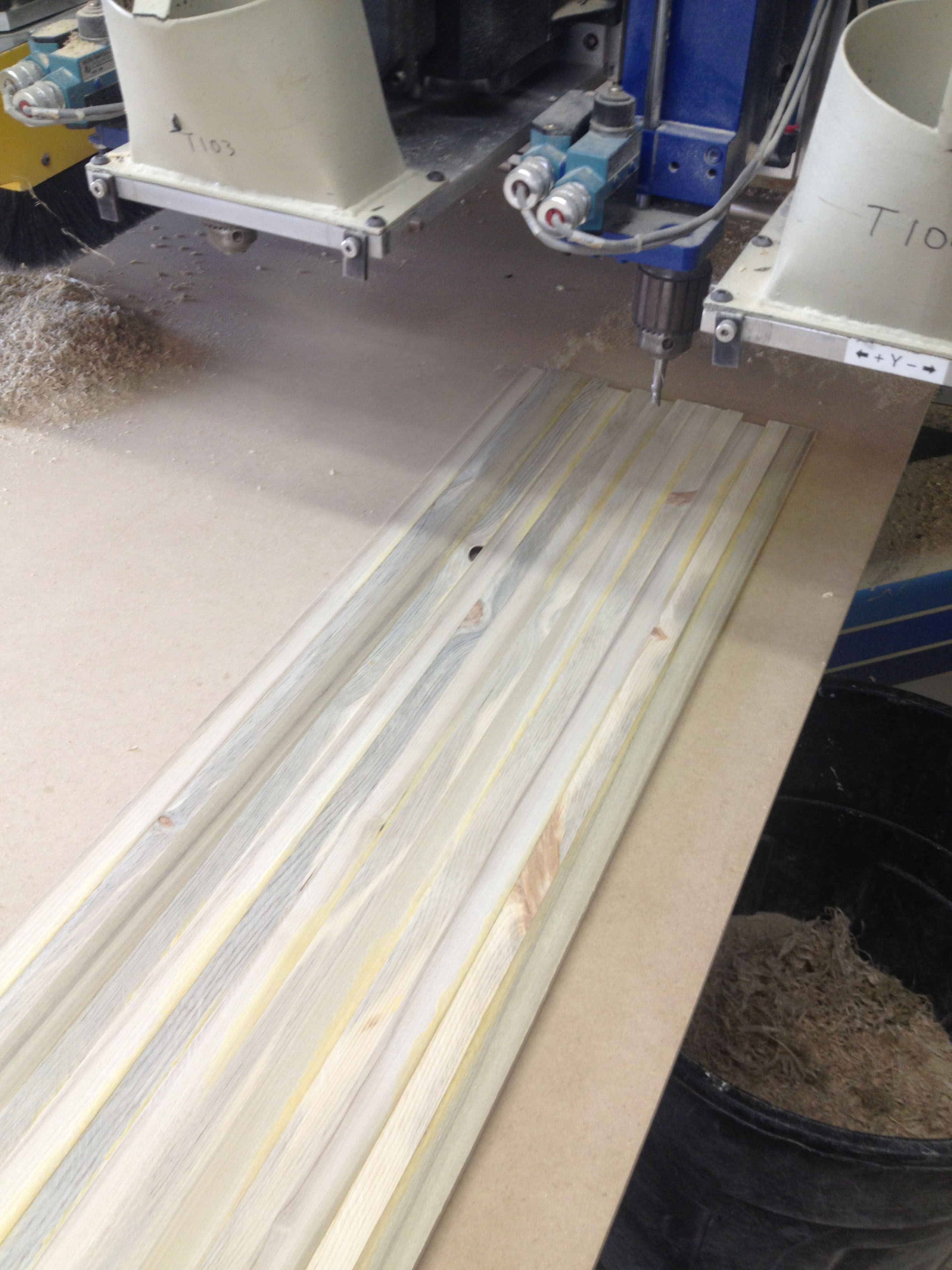

Talk about some serious pressure--Weston's press.

Talk about some serious pressure--Weston's press.

Clark calls Weston and Karakoram kindred spirits. “They’re from Washington State; they’re a small company. You get Bryce or Tyler when you call,” explains Clark. “They’re stoked to work with smaller companies. We’re not Mervin or Rome; we’re small like they are.”

Karkoram’s hardware is a linchpin for Weston’s ability to experiment with newer, less mainstream splitboard shapes. If your split performs more like a solid, you have the ability to give the board manufacturer better feedback about the design.

Karakoram uses an active-joining technology instead of a passive attachment in its board clips and binding system, which effectively pull the halves of a splitboard together to make the board perform like a solid. To visualize this, think of a toolbox clamp (which mirrors Karakoram’s hardware) versus two hooks that slip into one another (which is the design used by most traditional hardware).

This Weston split sports a carbonium topsheet

“Passive attachment is something that hooks together,” Kloster explains. “There is nothing that is loading the system. A slip fit needs clearances. You’re going to have things that move around. They are tight initially, but they end up with a sloppier fit over time.”

Kloster also emphasizes that Karakoram’s design transmits energy more effectively and efficiently. “When you have the active attachment, parts don’t move relative to each other. They move together,” he explains. “You’ll be transmitting that force faster through our system. The sides of the board perform as one, so the seam of the board doesn’t sheer. [The two sides of the board] are able to transmit torsion together as one instead of independently.”

Shaping Boards—Mad Scientist-style

“Our goal is to create an awesome snowboard for riders who do 100-plus days on the mountain,” explains Clark. “Our target is core riders with a high-level of skill and who can ride the type of product we are putting out.”

This philosophy informs Clark’s experimentation with new shapes and profiles for both splits and solids. One of the unique shapes Weston will be putting out is the Line of Control. Designed by Mike Whitfield, a Vail-based big mountain guru, LOC is the most aggressive snowboard in the company’s portfolio.

“Compared to like a [Burton] Custom X, which is meant for a large segment, the Line of Control has a narrow scope,” says Clark. “It’s made for skilled big mountain snowboarders. It’s going to be that board you want under your feet where you are in Japan or Alaska. It’s the kind of board you feel safe on when you are hitting those lines where literally you make a wrong turn and you are dead.”

Tested at Valle Nevado, Chile this summer, the first generation Line of Control has a bigger sidecut than anything else Weston produces. With a progressive flex and a nose that is softer than the deck’s tail, the board rides smoothly in Colorado’s inevitably variable conditions.

The Line of Control also aims to help riders lay down fluid turns. “Athletes are coming from a different background right now, having such a lust to go light and shorter,” Whitfield explains. “New backcountry riders stay light and feathery, closing turns out. I like to finish my turn with the nose of the board down the fall line. More experienced backcountry riders understand bigger, stiffer platforms that are still loose and nimble are more effective.”

“To a certain degree, I think that there is a big change when you have been riding the resort a long time and riding backcountry,” Whitfield offers. “If someone who rides the groomers and park with a great deal of power can learn to ride these bigger platforms, they can ride with the same style and finesse they do on the resort in the backcountry.” And luckily for these riders, Weston is ready to meet their needs—and respond to their feedback.

To learn more about Weston, drop into https://www.westonsnowboards.com/